Ottawa, ON Canada – The Shaw Centre

25th – 29th July 2016

Ottawa, ON Canada – The Shaw Centre

25th – 29th July 2016

Why So Many Customers Choose SinoGuide Technology

Small details make big difference. We promise: All the parts from our company have no sh-arp edge. Every product will be carefully packed to prevent the bump and rust in transit .

Our range of products provides different solutions for the thermal management of LED light components. All of our products are RoHs- and CE-compliant.

Thermal interface materials (TIMs) play an important role in the electronics manufacturing industry. Electronic components generate heat. Excess heat needs to be discharged or the life of the electronic device could be drastically shortened. Typically, fans and heat sinks (and heat sink fans) are used to dissipate heat in electronic devices, but as electronics mature, so do the materials used to construct them. Some of these thermal interface materialsinclude:

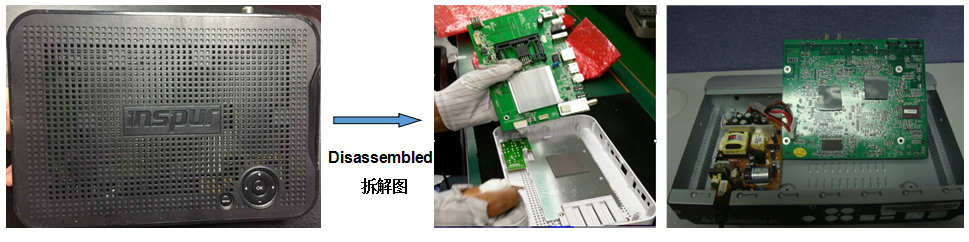

Set-top Box Application

- Pads applied between PCB and housing to -Application scene: Heat Source (Chips) and Heatsink (Casing)

-Applied material: soft and high thermal conductive pads

TIMs Application:

Thermal interface materials can be used in a wide range of electronic products ranging from automotive electronics, telecom, consumer, lighting, military, medical, power supplies, wireless, personal computer, LED, LCD TV, motherboard, DRAM memory module, cooler, vehicle control module, notebook computer etc…wherever there is thermal management issues AOK's products can provide a cost-efficient and manufacturing-friendly solution.

Alternatively referred to as heat dope, heat sink jelly, heat sink paste, heat sink compound, thermal gunk, and silicon compound, thermal compounds is a sticky paste that is placed directly onto the CPU, allowing for a more direct heat transfer between it and the heat sink. It also prevents air gaps from forming between the CPU and heat sink. The advantage of using a liquid dispensable Gap Filler is the ability to apply the material to very specific areas and at varying thicknesses, thus offering commercial and technical advantages.

Today we are kicking off a two part series on thermal conductivity and how to use this property to choose a thermal insulators. Thermal conductivity is important since it can help you make the best choice of material for a thermal interface materials. Thermal Pad are often the default choices but are there are other choices of thermal interface materals for heat transfer.

1. Commission Unit: AOK sales Dept.

2. Sample Description:

SinoGuide Technology has introduced specially formulated thermal interface pad materials that simplify board-level maintenance by reducing material tearing during disassembly for re-work and repair. TCP and TC series thermal interface materials feature a unique hardened top surface. This one-sided surface treatment is less tacky than the opposing contact side, allowing the thermal pad material to consistently adhere to either the electrical component or opposing heat sink. The hard surface releases quickly and easily from its component without tearing or damage. TCP and TCI series thermal pad materials are available in seven different formulations and offer thermal conductivity from 1.0 to 7.5 W/m.K.